CUSTOMER PROFILES

Customer profile

The extrusion plant produces and processes aluminium profiles to order. As a result of modern extrusion technology, the use of the aluminium profile is continually increasing. Extrusion technology and low tool costs provide the designer with great freedom to design different profiles to fit each desired use. In addition to our traditional customers, the building and machine construction industries, aluminium has also grown more popular as a solution in the transport, electrical and electronics industries.

|

Swiftly from designer's desk to product.

|

Purso Oy has invested in the latest state of the art technology

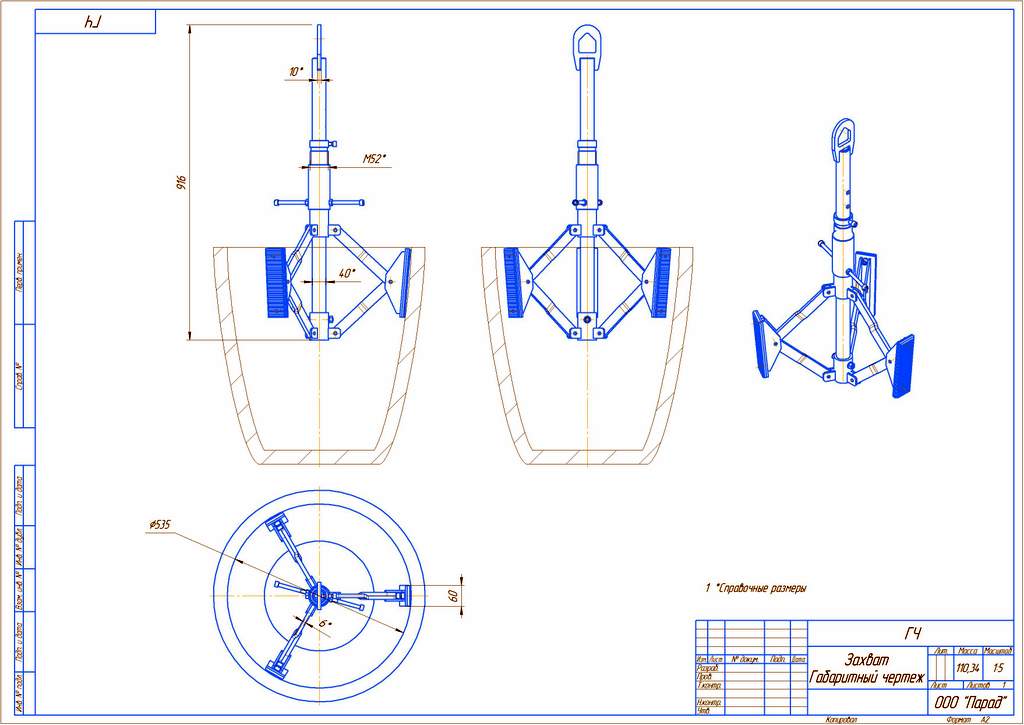

A new extrusion line, one of the most modern in Europe, is now in full operation. With a pressure of 35 MN profiles up to 300 mm in circumscribing circle diameter can be extruded. The factory building was extended with 3.500 square meter for the new line.

Purso profiles

Purso Oy has three extrusion lines with respective extrusion forces of 35, 20 and 16 MN. They are best suited for producing profiles weighing 0,2-20,0 kg/m. Machining and surface treatment of profiles is part our services.

Technical parameters of extrusion plant

| Circumscribing circle diameter (c.c.d.) | 170 - 300 mm (depends on profile shape) |

| Wall thickness | min. 1,2 mm |

| Weight max. | 20 kg/m |

| Weight min. | ~ 0,200 kg/m |

| Min. delivery | 250 kg |

| Max. length | 16 m |

| Max. length, surface treated | 7,5 m |

| Weight / length | max. 100 kg |

| Tolerances | EN 755 / EN 12020 |

Available alloys

| EN AW-6063 | DIN AlMgSi0,5 | The most common extrusion alloy. Good tenacity, very suitable for anodizing. |

| EN AW-6060 | - | Somewhat softer than EN AW-6063 |

| EN AW-6005 | DIN AIMgSi0,7 | Somewhat better tenacity than 6063. Suitable for anodizing. |

| EN AW-6082 | DIN AIMgSi1 | Construction alloy with very good tenacity, not suitable for anodizing. |

| EN AW-6101 | DIN E-AIMgSi0,5 | Good electric conductivity, good tenacity. |

The Light Metal Workshop

Purso refines aluminium for components. Purso Ltd is known as an expert in aluminium, and not without reason. The company masters the entire manufacturing chain of aluminium products ? from billets to components ordered by the customer. Precise design, accurate manufacturing and timely delivery are performed with professionalism typical to Purso Ltd.

Full Service

The co-operation between the customer and Purso Ltd starts with the design of the required component. This Combines the will of the customer and the facilities of Purso Ltd. After the optimal solution has been found, it is time for the different manufacturing stages: machining, cleaning, finishing, assembly and inspection. When a product is finally packed for delivery, it bears the Purso quality stamp.

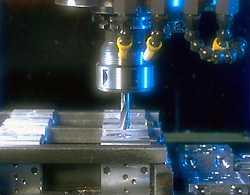

Highly Efficient Production Guarantees Ouality

The heart of Purso Ltd's aluminium component manufacturing is a two-pallet CNC-controlled machining centre combined with an ultrasound washing unit. This unit is well-suited for the serial manufacturing of various components economically, and without sacrificing high quality.

The special skills

The special skills of Purso Oy are the bending of aluminium profiles by programmable bending units, and joining aluminium with TIG- and MIG- methods.

The basic data of Light Metal Workshop

| Cutting: | Straight and angled precision cutting |

| Punching: | Hydraulic and eccentric presses |

| Machining: | CNC-machines |

| Turning: | Subcontracted |

| Bending: | Programmable- and press bending machines |

| Welding: | TIG and MIG welding |

| After treatment: | Drumming etc. |

| Cleaning: | Ultrasound washing |

| Assemble: | Manual assembling |

| Packing: | Plastic protection machine, and custom packages |