SURFACE TREATMENT

Surface treatments

Surface treatments

Aluminium receives an extra coating

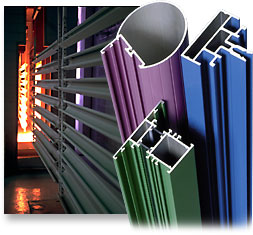

The silvery surface of aluminium is as such often ready for several purposes. It is, however, quite soft and turns shabby after a while. Visual aspects and a number of practical reasons call for surface treatment to give aluminium the final touch that satisfies the demanding customer.

Surface treatment further improves aluminium's natural resistance to corrosion and lengthens its life. It gives a hard and smooth surface which is tidy, durable and easy to keep clean. The development in surface treatment methods has not only improved treatmentresults but also cut costs and opened possibilities to offer traditional aluminium products a completely new guise, with all the colours of the rainbow, if you like.

Quality and experience

Purso Oy has four decades of experience in the surface treatment of aluminium. We can offer both anodizing and powder coating of aluminiumprofiles as well as sheets and piece goods. Through tests and laboratory experiments, and by engaging in close cooperation with independent research institutions we strive to constantly raise our quality standard.

New colourful possibilities and durable surface

New colourful possibilities and durable surface

Powder coating renders excellent mechanical and chemical resistance and a large number of colour options. Normally the tones of RAL- colourmap are used, but also other tones are possible. To improve the adhesion and bonding of the powder the material to be painted is prepared by yellow chroming.

The requirements placed on painted surface affect the choise of powder type. Polyester powder is suitable for purposes for where high weather resistance, and resistance to yellowing through UV-light or heat is required. Profiles intended for indoor use are coated with polyester or epoxy paints, or mixture of these. Epoxy powder provides exeptional resistance to corrosion and it is tolerant against acids, alkalies, greases and solvent. The process of our powder coating plant fulfills the requirements of GSB standard.

Anodizing enhances aluminium's appearance and natural resistance to corrosion. Anodizing is a special surface treatment method for aluminium whereby an oxide layer is formed on the surface of the metal in an electrochemical process. In anodizing, the objects to be treated are immersed as the anode in an electrolyte. When an electric current is passed through the solution, oxygen is released and reacts with aluminium forming an oxide layer on its surface. The thickness of the layer can be regulated by changing the electric current, the treatment time. or the composition of the electrolyte. The resulting surface is extremely hard, dense, and durable, enchancing the natural metallic appearance of aluminium.

Anodizing enhances aluminium's appearance and natural resistance to corrosion. Anodizing is a special surface treatment method for aluminium whereby an oxide layer is formed on the surface of the metal in an electrochemical process. In anodizing, the objects to be treated are immersed as the anode in an electrolyte. When an electric current is passed through the solution, oxygen is released and reacts with aluminium forming an oxide layer on its surface. The thickness of the layer can be regulated by changing the electric current, the treatment time. or the composition of the electrolyte. The resulting surface is extremely hard, dense, and durable, enchancing the natural metallic appearance of aluminium.

Purso uses three different anodizing methods:

- Natural anodizing (LV) for indoor and outdoor use, one tint and several layer thicknesses.

- Colour anodizing (S) for indoor and outdoor use, 3 golden tints.

- Electrolytic coloranodizing (ES) for indoor and outdoor use, 7 standard tints.

Colour options:

The samples of colour shown on the screen may depart from the real tones.

On request we deliver anodised sample pieces.